Virtual Total Productive Maintenance Program

Total Productive Maintenance (TPM) is a lean manufacturing approach designed to address equipment breakdowns, high maintenance repair costs, missed deliveries & quality problems due to equipment issues.

The goal of TPM is to achieve zero losses – no accidents, no defects and no unplanned downtime. As a result, many companies experience a 15% or better cost reduction and ship on time, every time.

Cohort Kicks Off

December 1, 2020

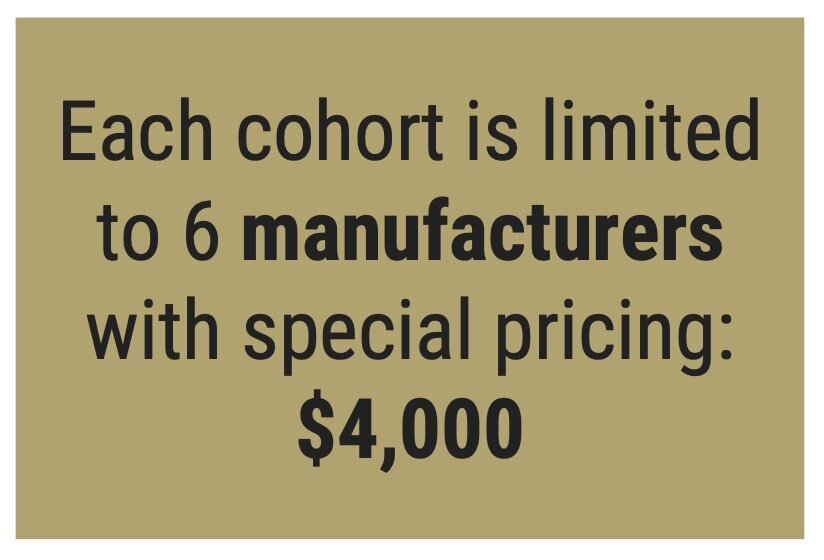

Each cohort is limited to 6 manufacturers with special pricing: $4,000

7 step process:

8 weekly virtual trainings will cover the steps to implement TPM for a select piece of equipment & teach you the skills to replicate this throughout your plant.

1. 6s Implementation

2. Address Contamination Sources

3. Inspect Equipment & Tag Defects

4. Establish Daily Inspection & Lube

5. Attack 6 Major Losses

6. Advanced Productive Maintenance

7. Sustaining TPM

Benefits:

15% + Maintenance Cost Reduction

Stepwise Approach, Guided by Experienced GaMEP Project Managers

Shared Learning and Best Practice Sharing alongside other Manufacturers Cost-Effective Implementation Approach

Schedule:

Dec. 1 : Establishing the Baseline Jan. 5: 6S Implementation

Jan. 12: Address Contamination Sources

Jan. 12: Inspect Equipment & Tag Defects

Jan. 19: Establish Daily Inspection & Lube

Feb. 2: Attacking the 6 Major Losses Feb. 9: Advanced Productive Maint. Feb. 16: Sustaining TPM

Each session is 2 hours + Implementation

Interested in joining?

Apply here: https://www.surveymonkey.com/r/D378XRL